PP sheet refers to polypropylene, PP sheet is propylene polymerization reaction of polymer, is a white waxy material, transparent and light appearance. PP sheet is made of polypropylene plastic sheet, PP plastic board lining is a semi-crystalline material, PP sheet relative to PE sheet is more rigid, PP plastic board lining melting point is higher. PP sheet has a certain heat resistance, low temperature impact, corrosion resistance and arc resistance, PP sheet has a shrinkage rate, PP sheet is an ideal building sheet in modern architecture. PP plastic board lining is also in line with the requirements of environmental protection of engineering plastic, PP board it tasteless, environmental protection and health.

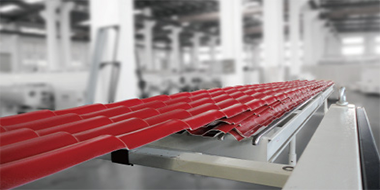

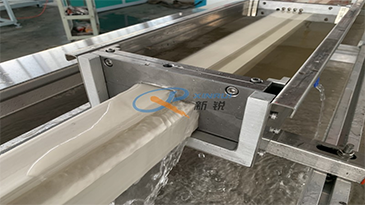

PP plate production line