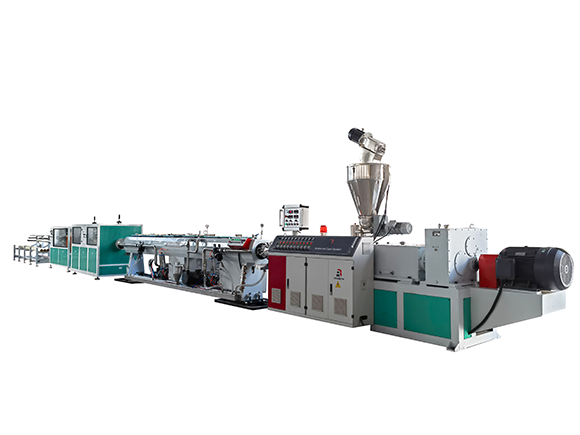

The PVC wood door extrusion production line is made up of conical twin-screw plastic extruder, broad mould, calibrator, cooling platform, crawler tractor, transverse cutting machine, and unload frame.

Key Features

- General wall and ceiling decoration

- Wall partitioning and ceiling conversion

- Feature walls

PVC pipe production line is mainly used in the production of PVC pipe,

The producing line can be adjusted according to clients’ requirements . What’s more, the line can work at high capacity and be easy to maintain. Normally this line is composed by eight parts ,as follow:

- Feeder

- conical twin-screw extruder

- pipe mould

- vacuum calibration tank

- Spraying box

- haul-off

7. cutter

8. staker

The mixer can also be equiped by requirement .

| Main Technical Parameters | |||||

| MODEL | PVCG-50 | PVCG-160 | PVCG-250 | PVCG-315 | PVCG-400 |

| MATCHED EXTRUDER | SJZ51/105 | SJZ65/132 | SJZ65/132 | SJZ80/156 | SJZ80/156 |

| OD RANGE(mm) | 16-50 | 50-160 | 75- 250 | 110-315 | 200-400 |

| LENGTH OF VACUUM CALIBRATOR TANK(mm) | 6000 | 6000 | 6000 | 6000 | 6000 |

| HAUL SPEED(m/min) | 0.6-6 | 0.5-5 | 0.4-4 | 0.3-3 | 0.2-2.5 |

| INSTALLED POWER(kw) | 67 | 85 | 95 | 125 | 135 |

| TOTAL LENGTH(mm) | 17000 | 18000 | 20000 | 20500 | 28000 |

Now start your business!

Supply Reliable Turn-key Project Solution of Plastic Extrusion