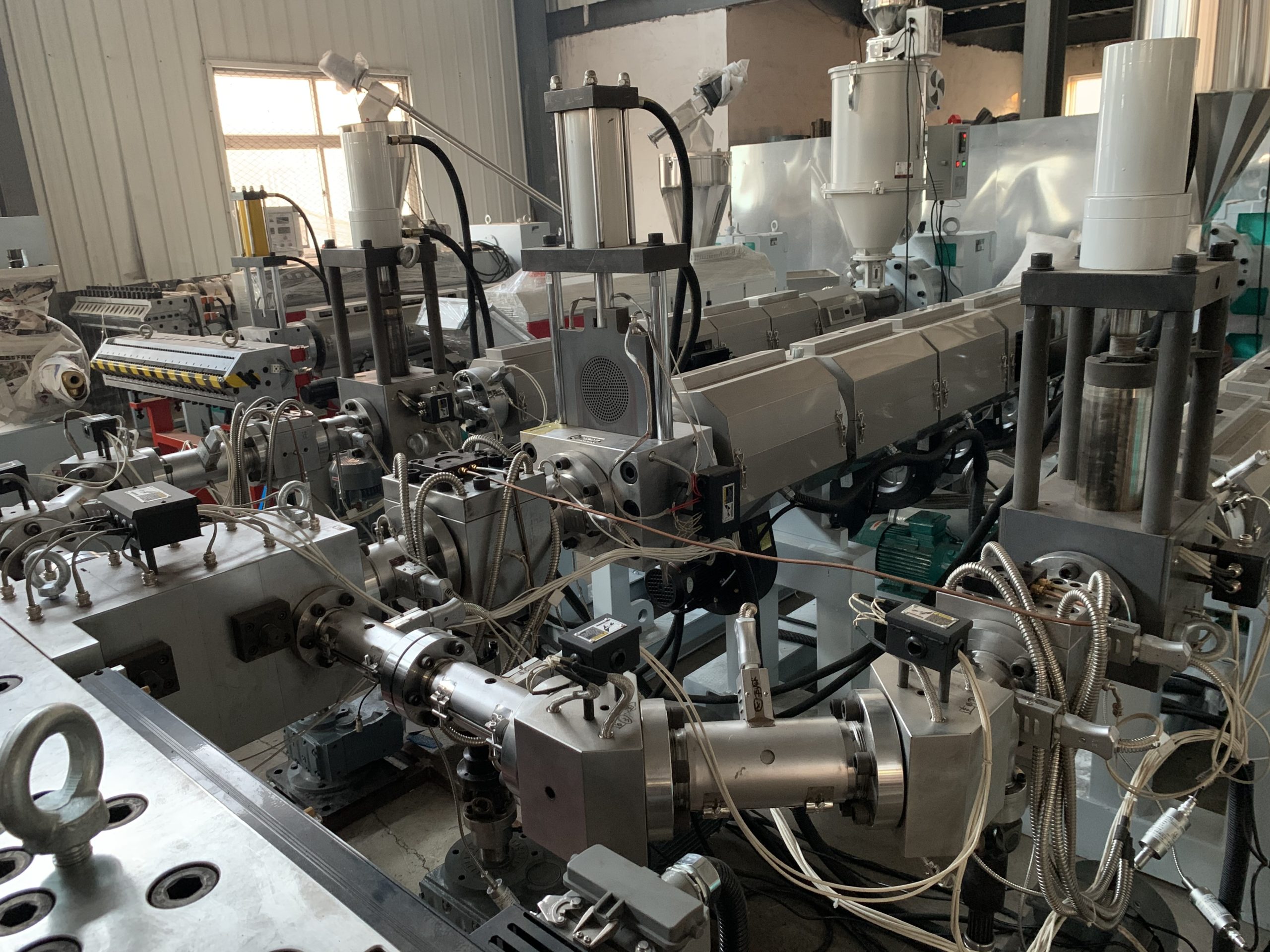

- Special screw design could

- efficiently increase the plasticization

- output up to 800kg/h.

Application:

ABS/PC Baggage sheet:

It is mainly applied in field of draw-bar boxes, luggage cases, recreation bags, etc.

ABS/HIPS/GPPS sheet:

It has wide application in production of refrigerator door and inner gallbladder, drawers, water dispensers, etc.

ABS/PMMA Sanitary ware sheet:

It is widely applied in the field of bath products, such as the bathtub, the shower cabinet, the vapor room, washing bowl, etc.

ABS + PC Car sheet:

It is mainly used in to produce tops of cars and buses, instrument boards, backrest, car doors, window frames, shells of the motorcycles, golf vehicles, etc

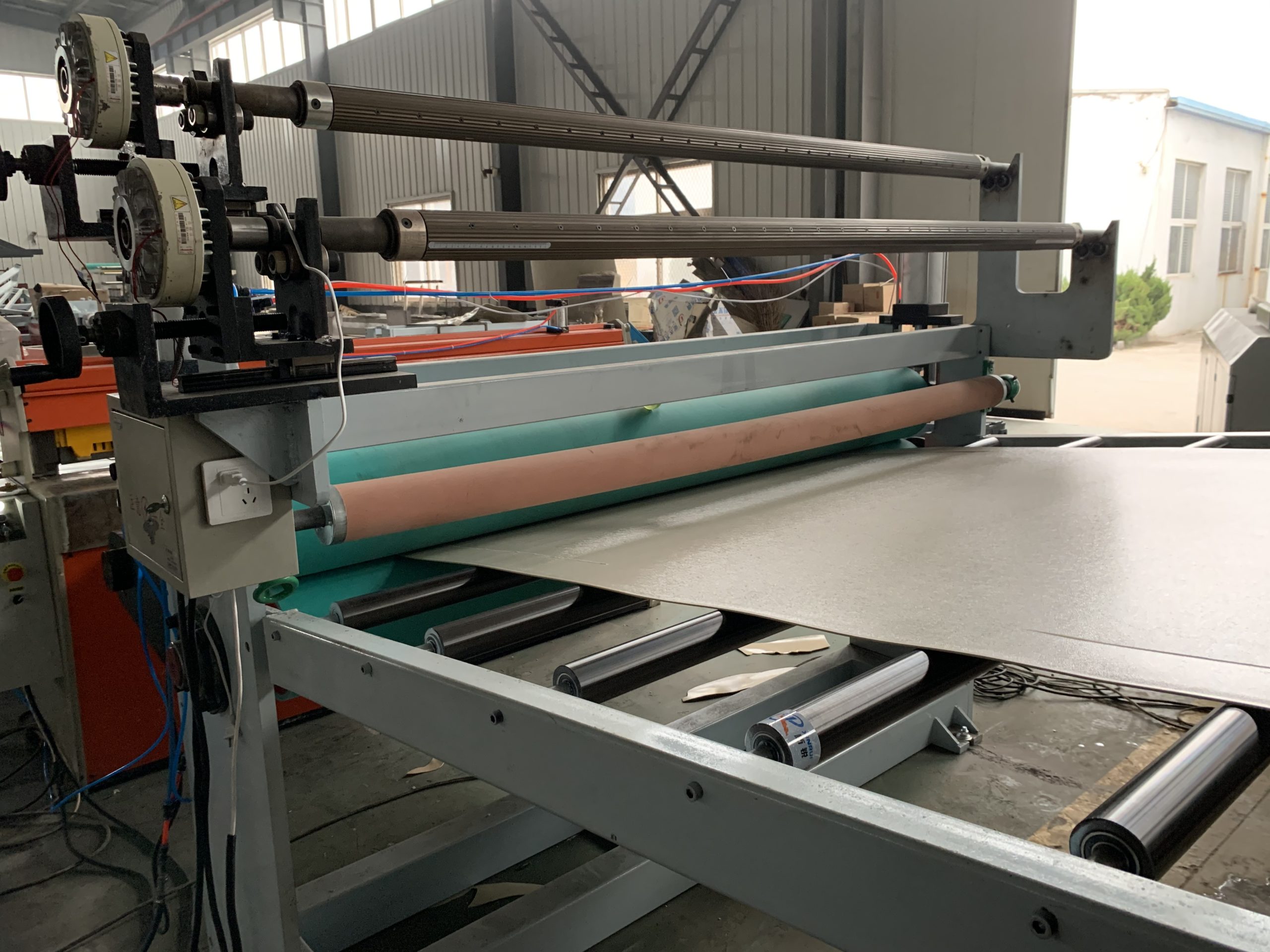

Sheet sizes:

Sheet dimensions:Width:1200-2500mm,Thickness:1-8mm,Length:customized.

Machine description:

1.Special screw design could efficiently increase the plasticization.

2.Coextrusion technology could produce both single-layer and multi-layer board.

3.Equipped with embossing system,this machine could produce embossing pattern ABS sheet.

4.Production line adopts Siemens motor,ABB inverter,Schneider contactor and Siemens PLC control system and Siemens touch screen.Reliable electrical components and special designed program could guarantee the machine running smoothly,save power and reduce the waste.

Now start your business!

Supply Reliable Turn-key Project Solution of Plastic Extrusion